Laser-Based mostly Inspection: Some Pick and Place machines combine laser-based inspection for Innovative quality Management. This method can determine defects or anomalies in elements or to the PCB, like solder joint irregularities or lacking factors.

These precision placers rely upon placement heads with comparatively several pickup nozzles. The pinnacle in some cases features a laser identifier that scans a reflective marker within the Computer board to orient the head to the board. Pieces are picked up from tape feeders or trays, scanned by a digital camera (on some machines), and afterwards placed in the right placement within the board. Some machines also Middle the parts on the head with two arms that near to center the component; The pinnacle then rotates 90 degrees as well as the arms shut again to center the section once more. The margin of error for many factors is less than fifty percent a millimeter (a lot less than 0.02 inches). [citation required]

We offer complete SMT methods that address each aspect of your manufacturing line. No matter if you’re assembling tiny parts or complex multi-layer PCBs, we customize the best pick and place machine on your precise prerequisites, guaranteeing maximum productivity and precision.

Every single component that is picked is analysed from the machines vision program right before placement to make sure that each of the programmed element Proportions match and likewise to check for any damage for instance bent sales opportunities.

Pick and place machine for smt efficiency enables producers to meet superior output calls for and tight deadlines without compromising quality. By streamlining the assembly line, providers can Raise their output and react much more effectively to sector alterations.

These machines are definitely the spine of modern PCB assembly lines, ensuring pick & place machine large throughput and responsible overall performance.

If you still have any dilemma, you should Speak to us by e-mail / skype/ cellular phone /trademanager online support.

Operational Performance: The Doing the job system will involve automatic procedures that considerably raise assembly pace and accuracy as compared to handbook solutions, reducing problems and minimizing creation fees.

When the Preliminary investment in SMT pick and place machines may look sizeable, the extended-term personal savings they supply are plain. By automating the placement process, makers can cut down labor expenses and decrease the chance of human mistake.

Companies very carefully Assess these elements to select the most appropriate machine style that aligns with their generation objectives and good quality specifications.

The type of business enterprise will likely have a big bearing on the choice as some machines are created especially for speed While others are more centered on adaptability.

Diminished Creation Time: They might substantially lessen the time required to assemble numerous PCBs, building them Price-effective in mass creation situations.

Component Dimension Verification: Laser measurement can be used to confirm the scale of elements, ensuring they fulfill exact specifications. That is vital for parts with specific dimensions necessities.

Offline programming is a vital facet of optimizing placement packages on pick-and-place machines:

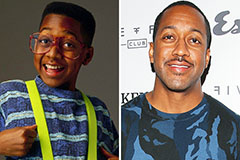

Jaleel White Then & Now!

Jaleel White Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!